Design and Functionality of Brass Manifolds

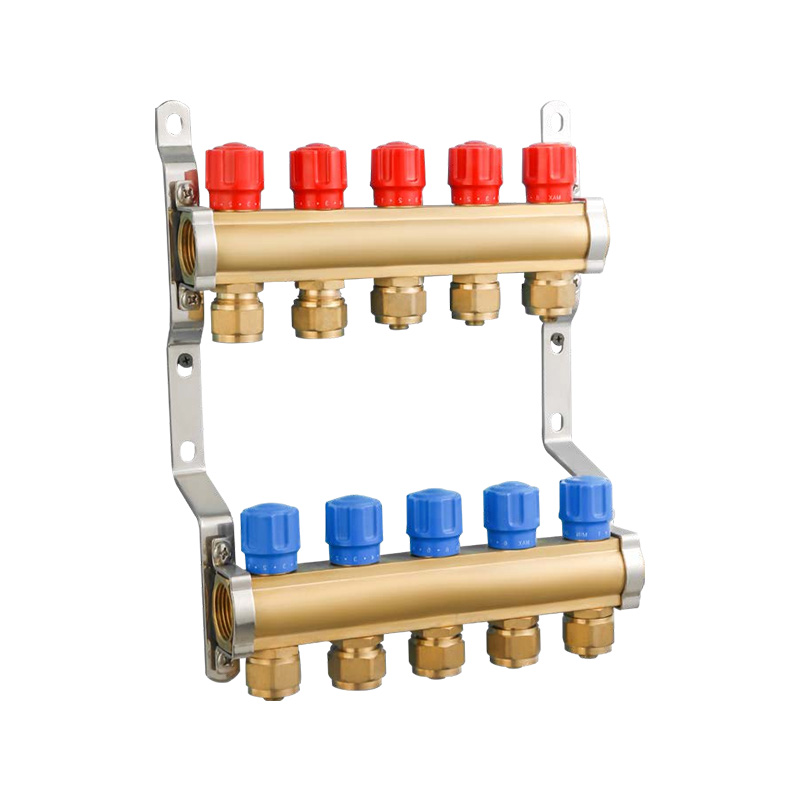

The design of a brass manifold is fairly straightforward but highly functional. It typically consists of a central body with multiple ports, through which fluid or gas can be directed to and from various parts of a system. The manifold serves as the junction point where the fluid is evenly distributed from a single source to several outlets. The ports on the manifold are usually threaded or flanged to allow easy connections to other piping or valves.

The main functionality of the manifold is to control and direct the flow of the fluid in a precise and controlled manner. In a heating or cooling system, for instance, the manifold distributes the flow of water or refrigerant to multiple radiators or cooling coils, ensuring that each section of the system receives the correct amount of fluid. The manifold may also include valves or flow meters to regulate the flow rate to each individual outlet, making it easier to balance the system and optimize performance.

Brass manifolds are often available in different configurations, such as single-stage, multi-stage, or modular designs, allowing for flexibility in installation. Their functionality is crucial for maintaining efficiency and reduce waste in fluid-based systems.

Material Properties of Brass Manifolds

The material used in the construction of the manifold is one of its key features. Brass is a mixture of copper and zinc, offering an balance of strength, durability, and corrosion resistance. These properties make brass ideal for use in manifold systems, where the component must withstand constant exposure to fluid under pressure without degrading over time.

Brass is highly resistant to corrosion caused by exposure to water, oils, and other industrial fluids, making it an ideal material for systems that handle corrosive substances or operate in humid environments. Additionally, brass offers good thermal conductivity, meaning it can dissipate heat efficiently, which is important in systems that involve temperature fluctuations or high-pressure flows.

Another advantage of brass is its malleability and ease of machining. Brass manifolds can be manufactured with precise dimensions and intricate designs, which is important for ensuring tight seals and preventing leakage. Unlike other metals, brass is relatively easy to fabricate, which helps keep production costs reasonable without compromising quality.

In summary, brass manifolds are designed to offer a combination of strength, corrosion resistance, and thermal efficiency, making them suitable for a wide range of industrial and residential applications.

Applications of Brass Manifolds

Brass manifolds have a wide range of applications across various industries. They are commonly used in heating, cooling, and plumbing systems to manage the flow of fluids. In hydronic heating systems, for instance, brass manifolds distribute water evenly to different radiators or heat exchangers. In underfloor heating systems, they ensure that the correct amount of warm water is directed to each zone, promoting even heat distribution and preventing energy wastage.

Brass manifolds are also integral to many industrial applications. In fluid and gas distribution systems, such as in chemical processing plants, manufacturing processes, and laboratories, they are used to manage the flow of various materials. The manifolds ensure that these materials are precisely directed to where they are needed, improving system efficiency and reducing the risk of spills or contamination.

Another common application of brass manifolds is in pneumatic systems. In these systems, air or other gases need to be distributed to multiple outlets. A brass manifold ensures that air pressure is evenly distributed to each output, maintaining the required flow rates and performance across the system. Brass manifolds are also often found in irrigation systems, automotive cooling systems, and even in medical gas systems, where precise fluid control is essential.

Advantages of Brass Manifolds

There are several advantages to using brass manifolds in various fluid and gas distribution systems. One of the main advantages is their durability. Brass is known for its long-lasting performance, especially when exposed to high temperatures, pressure, and corrosive environments. This makes brass manifolds ideal for applications that require reliable performance over long periods of time, such as in heating, cooling, and industrial systems.

Another key advantage of brass manifolds is their resistance to corrosion and wear. Brass is much more resistant to corrosion compared to materials like steel or aluminum, especially when exposed to water or chemicals. This ensures that the manifold maintains its structural integrity and functionality even after years of use. As a result, brass manifolds are less likely to need repairs or replacements, contributing to lower maintenance costs.

Additionally, brass manifolds are highly versatile. They can be used in a wide range of applications, from residential plumbing to industrial fluid systems, due to their ability to handle different types of fluids and gases. Brass’s malleability allows for easy customization in terms of size, configuration, and port designs, making it a flexible solution for various system requirements.

Finally, brass manifolds are easy to install and maintain. Their design, combined with the material’s durability, allows for straightforward installation in a variety of configurations. Regular maintenance is minimal, and the manifold can last for many years without requiring significant attention.

English

English русский

русский Español

Español عربى

عربى